Hadrian, a machine parts startup, recently raised $90 million, emphasizing its commitment to disrupt the aerospace supply chain. With investments totaling nearly a quarter billion dollars, Andreesen Horowitz and Lux Capital are leading this funding. Hadrian's focus on innovative technologies and manufacturing processes aims to revolutionize the industry. By prioritizing efficiency through automated CAD/CAM processes and palletized automation, Hadrian sets out to optimize supply chain operations and reduce costs. The $90 million investment signifies a major step towards reshaping aerospace manufacturing. Learn more about how Hadrian's advancements are poised to elevate the aerospace sector.

Key Takeaways

- Hadrian raised $90 million in funding to revolutionize aerospace supply chain.

- Investors include Andreesen Horowitz and Lux Capital, indicating industry confidence.

- Focus on automation, precision machining, and material advancements for efficiency.

- Hadrian aims to disrupt traditional production methods in aerospace.

- Strategic emphasis on Steel, Titanium, and Inconel materials for machining.

Hadrian's Impressive Funding Round

Hadrian's impressive funding round of $90 million, led by Andreesen Horowitz and Lux Capital, signals a significant milestone in the startup's journey to disrupt the aerospace supply chain. This substantial investment not only showcases the confidence that major investors have in Hadrian but also provides the company with the financial backing needed to propel its expansion and innovation within the aerospace sector.

Securing $90 million places Hadrian in a prominent position as a key player in revolutionizing the aerospace supply chain, indicating a shift towards more efficient and advanced manufacturing processes in the industry. The funding round not only benefits Hadrian but also reflects a broader trend of increasing interest in aerospace technology and the potential for significant industry-wide advancements.

With this substantial financial backing, Hadrian is poised to make significant strides in reshaping how machine parts are produced and supplied in the aerospace sector.

Disrupting Aerospace Supply Chain

Hadrian's recent $90 million funding injection marks a significant step towards disrupting the aerospace supply chain. By introducing innovative machine parts technology, the company aims to overhaul traditional production methods, enhancing automation and efficiency in the industry.

This strategic focus on supply chain transformation has the potential to not only drive cost savings but also elevate the competitiveness of aerospace companies in the market.

Supply Chain Innovation

Revolutionizing the aerospace supply chain, Hadrian, a machine parts startup, recently secured $90 million in funding to drive innovation and efficiency within the industry.

With a focus on leveraging cutting-edge manufacturing technology, Hadrian aims to transform traditional practices in the aerospace sector.

The company's primary objective is to revolutionize how business is conducted in aerospace, addressing critical issues such as labor shortages and operational inefficiencies that have long plagued the industry.

Industry Disruption Strategies

With a strategic focus on challenging conventional norms in the aerospace industry, Hadrian is set to implement disruptive strategies aimed at reshaping the supply chain landscape. The company, having raised $90 million, seeks to shake up the industry through innovative approaches. Here are some key strategies Hadrian is employing:

- Introducing cutting-edge machine parts technology to streamline production processes.

- Collaborating closely with aerospace companies to customize solutions for their specific needs.

- Implementing advanced quality control measures to guarantee precision and reliability in every part produced.

- Leveraging data analytics to optimize supply chain efficiency and reduce costs for clients.

- Continuously investing in research and development to stay ahead of market demands and technological advancements.

Market Impact Analysis

The infusion of $90 million into Hadrian's innovative machine parts technology is poised to greatly disrupt the aerospace supply chain. With this substantial investment, Hadrian seeks to revolutionize production processes within the aerospace industry, reflecting a shift towards more efficient and technologically advanced manufacturing methods.

The start-up's focus on disrupting the traditional aerospace supply chain indicates a significant potential for cost savings and increased efficiency for aerospace companies in their supply chain operations. This funding round not only showcases investor confidence in Hadrian's capabilities but also signifies a growing interest in aerospace technology and the potential for widespread industry impact.

Palletized Automation Advantages

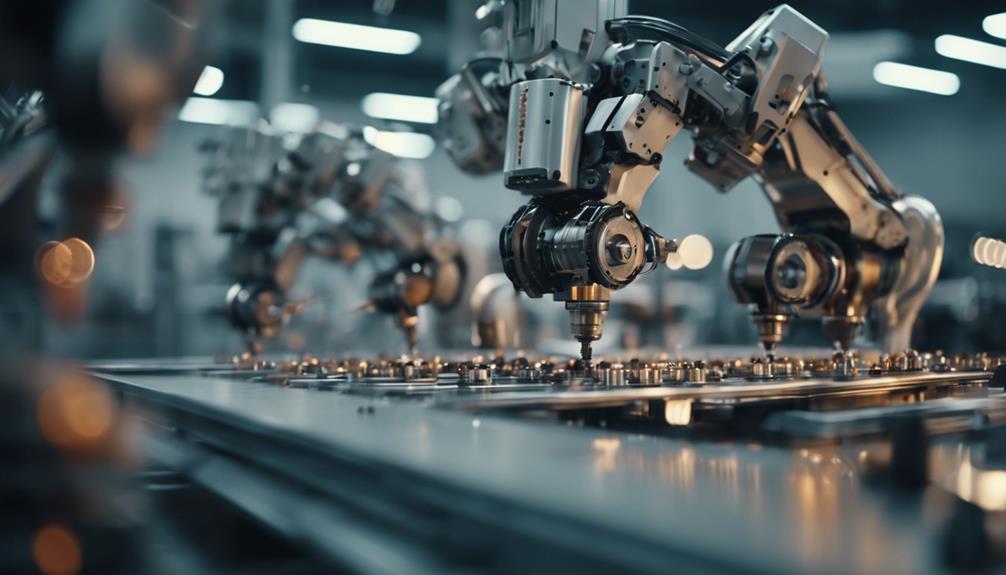

Palletized automation in Hadrian's manufacturing processes greatly enhances efficiency and productivity. This innovative approach to manufacturing machine parts provides several advantages:

- Streamlined Workflow: By utilizing palletized automation, Hadrian can optimize the flow of materials and components through its manufacturing processes, reducing bottlenecks and delays.

- Increased Output: The automated nature of palletized systems allows for continuous production cycles, leading to higher output levels compared to traditional manual methods.

- Enhanced Precision: Automation guarantees consistent and precise machining of parts, improving overall product quality and reducing the likelihood of errors.

- Resource Optimization: Palletized automation enables Hadrian to make efficient use of resources such as raw materials, energy, and labor, contributing to cost savings and sustainability.

- Scalability: The modular nature of palletized automation systems allows for easy scalability, facilitating the adaptation of manufacturing processes to meet changing demand levels efficiently.

Enhanced Machining Capabilities

Hadrian's enhanced machining capabilities revolutionize the production of aluminum parts, paving the way for future expansions into Steel, Titanium, and Inconel machining. By leveraging palletized automation and potentially automated CAD/CAM processes, Hadrian aims to push the boundaries of manufacturing efficiency.

The startup's focus on aluminum machining showcases its commitment to delivering high-quality components while also setting the stage for diversifying its material capabilities. Through these enhanced machining capabilities, Hadrian claims to achieve 3-10X efficiency compared to traditional machine shops, signaling a significant leap in productivity and cost-effectiveness.

With a strategic emphasis on automation and advanced machining techniques, Hadrian positions itself at the forefront of innovation in the aerospace supply chain. As the company secures substantial investments totaling around a quarter of a billion dollars, its vision to catalyze a democratic, abundant, spacefaring future through efficient manufacturing practices appears increasingly tangible.

Efficiency Over Traditional Methods

With its enhanced machining capabilities, Hadrian's disruptive efficiency levels outpace traditional methods by 3-10X, positioning the startup as an industry frontrunner in aerospace manufacturing innovation. This exceptional efficiency is vital in revolutionizing the aerospace supply chain and streamlining production processes.

The following points highlight Hadrian's efficiency over traditional methods:

- Hadrian claims to deliver 3-10X efficiency compared to traditional machine shops.

- The startup focuses on machining aluminum parts currently and plans to expand to Steel, Titanium, and Inconel soon.

- Hadrian emphasizes palletized automation for manufacturing, enhancing overall efficiency.

- The company's potential integration of automated CAD/CAM processes showcases a commitment to optimizing efficiency further.

- Hadrian's goal of accelerating a democratic, abundant, spacefaring future highlights its dedication to efficient manufacturing practices that can reshape the aerospace industry.

These factors position Hadrian as a key player in driving efficiency improvements within the aerospace supply chain, setting new benchmarks for productivity and innovation.

Revolutionizing Aerospace Manufacturing

Hadrian's approach to revolutionizing aerospace manufacturing involves:

- Advanced materials integration

- Automated production systems

- Supply chain optimization

Advanced Materials Integration

Integrating advanced materials into aerospace manufacturing processes is poised to revolutionize the industry's capabilities and efficiency. Hadrian, with an investment of around $1/4 billion, is focused on incorporating materials like aluminum, steel, titanium, and Inconel into its manufacturing capabilities. This strategic move aims to expand beyond traditional aluminum parts, enhancing the company's machining proficiency with various advanced materials.

The startup's emphasis on palletized automation and automated CAD/CAM processes aligns with its goal of achieving efficient manufacturing practices with these advanced materials. By introducing advanced materials integration, Hadrian is accelerating the development of a democratic, abundant, and spacefaring future within the aerospace industry.

- Hadrian is investing heavily in advanced materials like aluminum, steel, titanium, and Inconel.

- The company aims to go beyond traditional aluminum parts in its manufacturing processes.

- Focus on palletized automation and automated CAD/CAM processes is central to Hadrian's strategy.

- The $1/4 billion investment has notably enhanced Hadrian's machining capabilities with advanced materials.

- Hadrian's introduction of advanced materials integration is driving progress towards a futuristic aerospace industry.

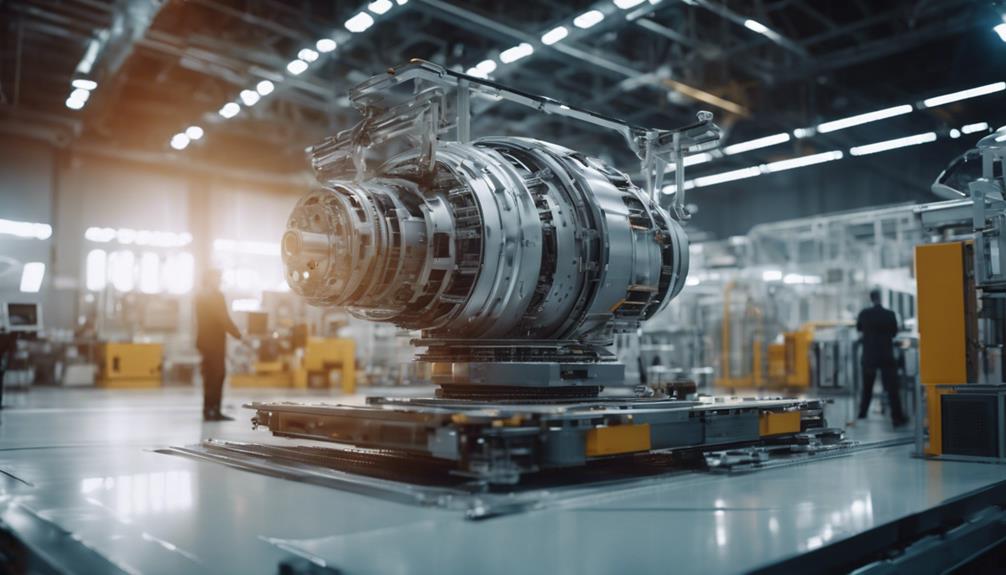

Automated Production Systems

Revolutionizing aerospace manufacturing, automated production systems deployed by Hadrian aim to deliver significant efficiency gains compared to traditional machine shops. Hadrian's automation systems target efficiency improvements ranging from 3 to 10 times that of conventional machining methods. The startup's current focus lies in machining aluminum parts, with a strategic roadmap to broaden its capabilities to include Steel, Titanium, and Inconel. By securing substantial funding, including $90 million in 2022 and $117 million in 2024, with investments totaling close to a quarter of a billion dollars, Hadrian demonstrates strong support for its innovative approach. The company places a premium on palletized automation and potentially automated CAD/CAM processes to streamline its manufacturing operations. This strategic emphasis aligns with Hadrian's overarching goal of propelling a democratic, abundant, spacefaring future through the adoption of efficient and cutting-edge manufacturing practices.

| Key Points | Details | Impact |

|---|---|---|

| Efficiency Improvement | Hadrian's systems aim to boost efficiency 3-10 times over traditional machine shops. | Enhanced productivity and reduced lead times. |

| Future Expansion Plans | The startup plans to extend its machining capabilities beyond aluminum to Steel, Titanium, and Inconel. | Increased versatility and broader market reach. |

| Financial Backing | Hadrian secured $90 million in 2022 and $117 million in 2024, totaling nearly a quarter of a billion dollars in investments. | Strong financial support for growth and innovation. |

Supply Chain Optimization

Efficiently optimizing the aerospace supply chain through advanced production processes is paramount for Hadrian's mission in transforming manufacturing practices. By focusing on automation and precision machining, Hadrian aims to revolutionize the aerospace supply chain, leading to significant efficiency gains.

The recent $90 million funding round secured by the company will play a pivotal role in supporting its endeavors to disrupt the aerospace manufacturing sector. Leveraging cutting-edge technology, Hadrian seeks to streamline the supply chain, ultimately reducing costs for aerospace companies. The start-up's dedication to machine parts innovation underscores its commitment to reshaping the aerospace industry.

- Automation and precision machining are key focus areas for Hadrian.

- The $90 million funding round will support Hadrian's efforts to transform the aerospace manufacturing sector.

- Advanced technology is being leveraged to streamline the aerospace supply chain.

- Hadrian's goal is to reduce costs for aerospace companies through supply chain optimization.

- The start-up's emphasis on machine parts innovation highlights its commitment to industry transformation.

Focus on Steel Machining

Hadrian's current emphasis on steel machining signifies a strategic shift towards diversifying its aerospace manufacturing capabilities. While the startup has primarily focused on machining aluminum parts, the decision to expand into steel machining reflects its commitment to catering to a broader range of aerospace manufacturing needs.

Steel is an essential material in the aerospace industry, known for its strength and durability, making it a pivotal component in aircraft construction. By investing approximately a quarter of a billion dollars into advancing its steel machining capabilities, Hadrian is positioning itself to meet industry standards for precision machining of steel parts.

This move not only demonstrates Hadrian's dedication to technological advancements but also underscores its ambition to become a key player in the aerospace supply chain. As Hadrian prepares to launch capabilities for steel, titanium, and Inconel, its strategic focus on steel machining sets the stage for a significant transformation in the company's manufacturing operations.

Targeting Titanium Materials

Hadrian's strategic decision to target Titanium materials signifies a significant shift in its material processing capabilities, aligning with the stringent requirements of aerospace manufacturing.

By expanding into Titanium, Hadrian aims to capitalize on the advantages offered by this high-strength, lightweight alloy, enhancing its offerings to meet the demanding needs of the aerospace industry.

This move not only showcases Hadrian's commitment to innovation but also highlights its intention to revolutionize the aerospace supply chain by incorporating Titanium into its repertoire.

Titanium Alloy Advantages

Titanium alloys stand out in aerospace applications due to their exceptional strength-to-weight ratio. These materials offer a multitude of advantages that make them highly desirable for various aerospace components:

- Corrosion Resistance: Titanium materials exhibit excellent resistance to corrosion, a crucial feature for aerospace parts subjected to harsh environmental conditions.

- Fatigue Strength: The superior fatigue strength of titanium alloys guarantees the durability of aerospace components that undergo repeated stress, contributing to the longevity of these parts.

- Biocompatibility: Beyond aerospace, titanium's biocompatibility makes it a suitable choice for medical implants, showcasing its versatility and applicability in diverse fields.

- High-Temperature Resistance: Titanium's ability to withstand high temperatures makes it a preferred material for components within aerospace engines and structures, ensuring operational reliability under extreme conditions.

- Weight Efficiency: In addition to strength, the lightweight nature of titanium alloys contributes to fuel efficiency and overall performance enhancements in aerospace applications.

These inherent characteristics of titanium alloys solidify their position as a top choice in the aerospace industry, offering a unique combination of strength, durability, and versatility.

Supply Chain Impact

Improving the machining processes for titanium materials in aerospace manufacturing is essential for streamlining supply chain operations and boosting overall efficiency. Hadrian, in its quest to revolutionize the aerospace supply chain, has set its sights on optimizing the production of machine parts using titanium.

Titanium's exceptional properties, including strength, lightness, and corrosion resistance, make it an indispensable material in aerospace manufacturing. By advancing the machining techniques for titanium parts, Hadrian aims to make significant strides in enhancing aerospace component production.

Given the aerospace industry's high demand for titanium parts, Hadrian's strategic focus on this material is poised to have a notable impact on the market. Through the optimization of titanium material machining processes, Hadrian seeks to not only improve the efficiency but also elevate the quality of aerospace supply chain operations.

This targeted approach underscores Hadrian's commitment to driving innovation and efficiency in the aerospace manufacturing sector.

Manufacturing Innovation

With a strategic focus on enhancing aerospace manufacturing capabilities, the startup is gearing up to revolutionize machining processes for high-performance materials. Hadrian is setting its sights on Titanium materials, alongside its existing focus on Aluminum, to broaden its manufacturing innovations within the aerospace industry. This targeted approach aligns with the company's objective of offering a more extensive range of solutions tailored to aerospace manufacturing needs.

- Hadrian aims to enhance its machining capabilities to include Titanium parts, renowned for their exceptional strength and durability.

- The decision to target Titanium materials reflects Hadrian's commitment to meeting the diverse material requirements prevalent in the aerospace sector.

- Titanium's prevalence in aerospace applications is attributed to its impressive strength-to-weight ratio and resistance to corrosion.

- By delving into Titanium machining, Hadrian underscores its dedication to pushing boundaries and meeting the evolving demands of aerospace manufacturing.

- This strategic pivot towards Titanium reaffirms Hadrian's position as an innovative force in the aerospace supply chain, poised to make significant contributions to the industry.

Advancements in Inconel Machining

Advancements in machining Inconel, a challenging material widely utilized in aerospace applications, are essential for Hadrian's innovative approach to revolutionizing the aerospace supply chain. Inconel, known for its high strength and heat resistance properties, poses challenges during the machining process, requiring specialized tools and expertise. Hadrian's upcoming capabilities for machining Inconel mark a significant step towards enhancing efficiency in producing critical aerospace components. Ensuring the precise machining of Inconel parts is paramount to guarantee the safety and reliability of aerospace systems. By mastering the machining of Inconel, Hadrian aims to gain a competitive advantage in serving the aerospace supply chain, potentially opening doors to new opportunities within the industry.

| Advancements in Inconel Machining |

|---|

| – Requires specialized tools and expertise |

| – Essential for safety and reliability of aerospace systems |

| – Potential to provide a competitive edge in the aerospace supply chain |

Industry Recognition of Potential

The substantial $90 million funding round secured by Hadrian underscores the industry's acknowledgment of the startup's disruptive potential in the aerospace supply chain. With notable investors such as Andreesen Horowitz and Lux Capital showing faith in Hadrian, the company's innovative approach to machine parts manufacturing is gaining significant traction within the aerospace sector.

This recognition not only validates Hadrian's capabilities but also highlights its growing influence on reshaping traditional supply chain dynamics in the aerospace industry.

Industry's Potential Recognition

Recognized for its disruptive potential in the aerospace supply chain, Hadrian secured a substantial $90 million in funding, showcasing industry confidence in its innovative approach. The investment from prominent firms like Andreesen Horowitz and Lux Capital further solidifies Hadrian's position as a key player in revolutionizing the aerospace supply chain.

The industry's acknowledgment of Hadrian's capability to bring significant changes to the sector is evident in the attention and support received from key players. With the milestone funding achieved, Hadrian stands out as a frontrunner in reshaping traditional supply chain dynamics within the aerospace industry. The growing interest in Hadrian's advancements underscores the industry's recognition of the start-up's potential to disrupt and innovate in this space.

- Hadrian's funding milestone demonstrates industry confidence in its ability to drive change.

- Investment from Andreesen Horowitz and Lux Capital signifies strong support for Hadrian's approach.

- Key players in the industry have shown attention and support for Hadrian's disruptive initiatives.

- Hadrian's position as a frontrunner in revolutionizing the aerospace supply chain is solidified by the substantial funding received.

- Growing interest in Hadrian's advancements reflects industry recognition of its potential to innovate the aerospace supply chain.

Impact on Aerospace Supply

Earning substantial funding and backing from industry giants like Andreesen Horowitz and Lux Capital, Hadrian is poised to have a profound impact on the aerospace supply chain with its innovative approach.

The $90 million investment signifies a strong industry acknowledgment of Hadrian's potential to revolutionize the way machine parts are manufactured for aerospace applications. By leveraging cutting-edge technologies and processes, Hadrian has attracted attention within the aerospace sector, with its advancements seen as a pivotal factor in enhancing production efficiency.

Analysts view Hadrian's recent funding round not just as a financial milestone but as a clear indicator of the startup's increasing influence in reshaping the aerospace supply chain landscape. The industry's recognition of Hadrian's technology as a catalyst for transformative change underscores the startup's position as a key player in driving innovation within the aerospace manufacturing domain.

As Hadrian continues to develop and implement its groundbreaking solutions, its impact on the aerospace supply chain is expected to be substantial and far-reaching.

Automated Future Prospects

What potential do automated future prospects hold for Hadrian's advancement in revolutionizing the aerospace supply chain?

Automation stands as a cornerstone in Hadrian's mission to transform the aerospace supply chain landscape. The injection of $90 million in funding elevates Hadrian's capacity to explore further into automated technologies, anticipating a future where efficiency and productivity soar to unprecedented levels.

The following points underscore the significance of automated future prospects for Hadrian:

- Enhanced Precision: Automation enables Hadrian to achieve unparalleled levels of precision in manufacturing processes.

- Increased Efficiency: Automated systems streamline operations, leading to enhanced efficiency and reduced production times.

- Cost Savings: Automation can result in cost savings through minimized errors and optimized resource utilization.

- Scalability: Automated processes offer scalability, allowing Hadrian to adapt swiftly to varying demands in the aerospace industry.

- Innovation Drive: Automation fuels innovation within Hadrian, propelling the company towards pioneering solutions in the aerospace supply chain domain.

Significance of $90 Million Investment

Hadrian's $90 million investment signals a pivotal step towards revolutionizing the aerospace supply chain through enhanced innovation and expansion efforts. This substantial funding round, led by Lux Capital and Andreessen Horowitz, marks a significant milestone for the machine-parts start-up.

Investor confidence in Hadrian's commitment to driving innovation and efficiency within the aerospace industry has been a key factor in attracting such substantial financial support. The $90 million investment not only validates Hadrian's strategic vision but also provides the necessary financial backing to propel the company's growth and development initiatives.

This infusion of capital will enable Hadrian to further enhance its technological capabilities, expand its operational capacity, and solidify its position as a disruptive force in the aerospace supply chain sector. With this significant financial backing, Hadrian is well-positioned to make tangible strides towards reshaping the industry landscape and setting new standards for excellence in innovation and efficiency.

Efforts to Boost Efficiency

In its pursuit of enhanced efficiency, Hadrian strategically focuses on delivering 3-10X improvement compared to traditional machine shops. The startup aims to revolutionize the aerospace supply chain by streamlining manufacturing processes and maximizing output. To achieve this goal, Hadrian has implemented several key strategies:

- Leveraging advanced technologies such as palletized automation to optimize production workflows.

- Expanding its machining capabilities from aluminum parts to more challenging materials like Steel, Titanium, and Inconel.

- Investing in potentially automated CAD/CAM processes to enhance design and manufacturing efficiency.

- Prioritizing scalability and adaptability to meet the evolving demands of the aerospace industry.

- Aligning its mission with the vision of fostering a democratic, abundant, spacefaring future through efficient and sustainable manufacturing practices.

Impact on Aerospace Industry

Efforts to boost efficiency in manufacturing processes could potentially revolutionize the aerospace industry through Hadrian's innovative advancements in supply chain optimization. By disrupting traditional supply chain models, Hadrian's technology has the potential to generate significant cost savings for aerospace companies.

The increased automation facilitated by Hadrian's advancements is poised to enhance production processes throughout the aerospace sector. The recent investment in Hadrian underscores a growing trend towards leveraging technology to drive progress in aerospace manufacturing.

Aerospace companies are positioned to benefit greatly from Hadrian's precision and quality improvements in machine-parts manufacturing. These advancements could lead to streamlined operations, reduced lead times, and heightened overall efficiency in the aerospace industry.

As Hadrian continues to push boundaries in supply chain optimization, the impact on aerospace manufacturing is expected to be substantial, potentially reshaping the industry's approach to production and setting new standards for efficiency and quality.

Future Innovation and Growth

With a substantial $90 million in funding secured, the outlook for future innovation and growth in the aerospace supply chain appears promising for Hadrian. The recent investment places Hadrian in a favorable position to propel its operations to new heights and broaden its market presence, paving the way for further advancements in the aerospace industry.

Key points to contemplate include:

- Scaling operations and expanding market reach to drive progress.

- Focusing on innovation and efficiency supported by recent investments.

- Establishing partnerships with major aerospace companies to leverage automation capabilities.

- Reshaping the aerospace manufacturing sector through continued technological advancements.

- Driving efficiency in production processes for long-term growth prospects.

These factors collectively indicate a strategic path forward for Hadrian, with the potential to revolutionize traditional practices within the aerospace supply chain and establish itself as a significant player in the industry.

Frequently Asked Questions

Who Owns Hadrian?

Lux Capital and Andreessen Horowitz, prominent investors in Hadrian, collectively own the startup. They lead the funding round and have a significant stake in its operations. Their confidence in Hadrian's potential is evident through their ownership structure.

Lux Capital and Andreessen Horowitz's involvement highlights their belief in the company's ability to innovate and disrupt the aerospace supply chain.

Who Is the Founder of Hadrian Startup?

Hadrian startup's founder is Chris Power. He also serves as the company's CEO, guiding its strategic vision.

Chris Power's pivotal role in shaping Hadrian's focus on disrupting the aerospace supply chain has been instrumental in the company's growth and success, including raising $90 million in funding.

His expertise in machine-parts manufacturing has established him as a notable figure in the industry.

Who Are the Investors in Hadrian Automation?

Lux Capital and Andreessen Horowitz are the investors in Hadrian Automation. They led the $90 million funding round, showcasing their belief in Hadrian's potential to revolutionize the aerospace supply chain.

These prominent venture firms' support indicates their confidence in Hadrian's vision for industry disruption. Lux Capital and Andreessen Horowitz's backing is pivotal in propelling Hadrian's growth and expansion efforts within the aerospace sector.

Conclusion

To sum up, Hadrian's substantial $90 million funding round signifies a major step towards revolutionizing the aerospace supply chain. With a focus on palletized automation and enhanced machining capabilities, Hadrian is poised to bring unprecedented efficiency to the industry.

This investment underscores the company's commitment to innovation and growth, paving the way for a future where traditional methods are replaced by cutting-edge technology.

The impact of Hadrian's advancements will unquestionably shape the future of aerospace manufacturing.